info@caliylark.com

Automotive

Automotive Industry

- The automotive industry demands high-speed production, reliable quality control, and continual innovation. From structural components to miniature electronics, precision metrology tools and additive manufacturing play a vital role in streamlining design cycles, reducing defects, and improving safety.

Product Sales Applications

Video Measuring Machine

Used for inspecting fine mechanical and electrical parts such as connectors, fasteners, and PCB mounts.

Portable 3D Laser Trackers

Ensure accurate alignment of vehicle frames, chassis, and suspension systems during assembly.

Fixed 3D CMM

Provide high-precision dimensional inspection of engine blocks, crankshafts, and transmission housings.

Metrology Software

Enables automated inspection routines, tolerance analysis, and SPC data reporting to meet APQP and PPAP requirements.

3D Printers

Produce design validation prototypes, jigs, and fixtures, reducing lead times and tooling costs.

Our Services

Rapid Prototyping

Helps test aerodynamic body panels, dashboard layouts, and ergonomic interiors before mass tooling.

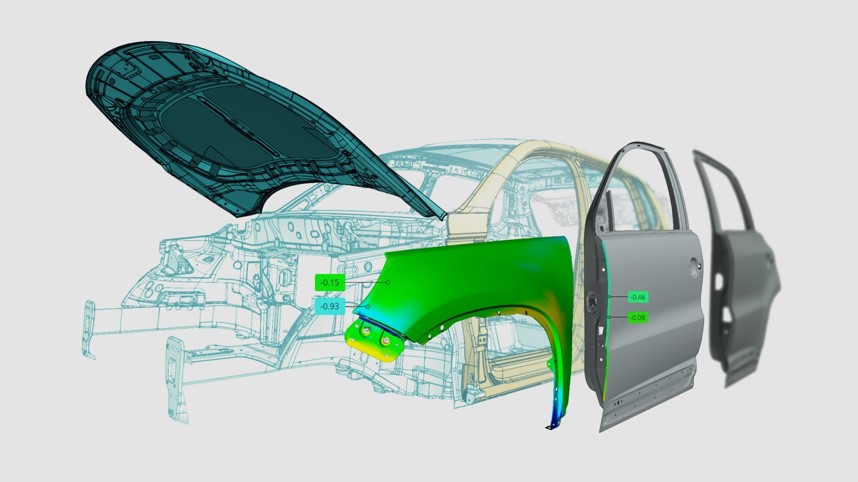

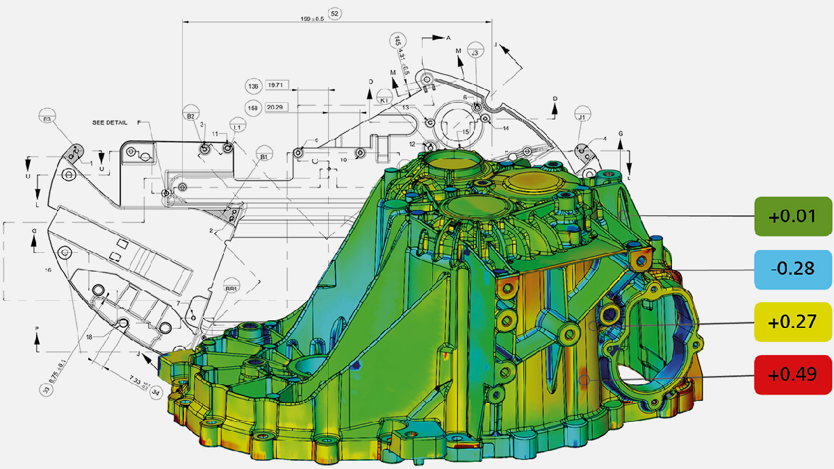

3D Scanning (3D Scanners, Portable CMMs)

Used for quality inspection, reverse engineering discontinued parts, or validating supplier components.

CNC Machining (CMMs & Inspection Tools):

Supports short-run production of high-tolerance components like brake calipers and steering knuckles.

Reverse Engineering (3D Scanners & Software)

Converts legacy or competitor parts into native CAD for benchmarking, redesign, or local sourcing.

Benefits to Automotive

Enhances build quality and structural integrity

Reduces rework and part rejection through in-line validation

Supports innovation in EV and autonomous vehicle platforms

Case Study

An automotive OEM reduced first article inspection time by 40% using a laser tracker and CMM combo. The system was integrated into the assembly floor, reducing delays caused by off-site lab measurements.

| Product | Application | Benefits |

| Portable CMMs | Shop-floor dimensional inspection | Mobility, ease of use, real-time inspection |

| Laser Trackers | BIW measurement, fixture calibration | High accuracy over large distances |

| 3D Scanners | Reverse engineering, surface analysis | Fast, non-contact, full-surface inspection |

| VMMs | Small precision parts (gears, valves) | Sub-micron accuracy for tight tolerance components |

| Coordinate Measuring Machines (CMMs) | Engine, chassis, transmission parts | Reliable for repetitive, automated measurements |

| Fiber Laser Markers | Part traceability and labeling | Permanent, non-intrusive markings on metal and plastic |

Let’s get started

Caliylark Technologies – Your Trusted Partner in Precision Engineering and 3D Solutions