info@caliylark.com

Locomotive & Railways

Locomotive & Railways

- The railway industry requires robust, scalable metrology to ensure the longevity and safety of tracks, rolling stock, and infrastructure. Large-scale components and frequent retrofitting make precision tools essential.

Our Products

3D Scanners

Inspect bogies, braking systems, and undercarriage structures.

Portable Laser Trackers

Validate structural alignment and profile railcar sections.

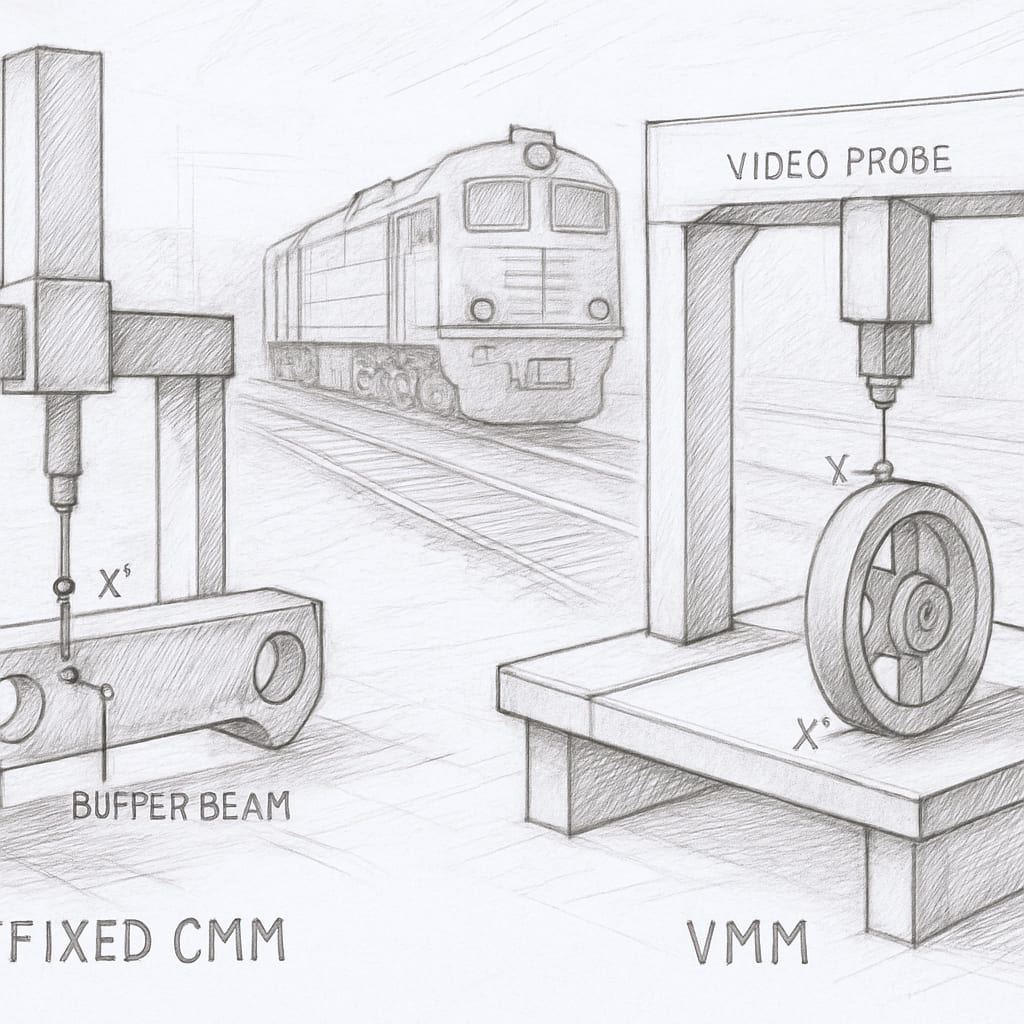

Fixed CMMs & VMMs

Validate precise dimensions of machined parts like axles, couplers, and bushings.

Fiber Laser Markers

Durable component labeling and traceability.

Our Services

3D Scanning (Portable Scanners & Trackers)

For rework inspection or infrastructure clearance checks.

Reverse Engineering

Rebuild aging components where documentation is obsolete.

Rapid Prototyping

Prototype carriage interiors or control panels for design improvements.

Benefits

Increases safety via thorough inspection routines

Supports modernization of legacy systems

Enhances availability of spares through reverse engineering

Case Study

A metro operator digitized their aging coupler design using reverse engineering, enabling local machining and slashing downtime from 6 weeks to 10 days.

Product | Key Applications | Benefits |

Laser Trackers | Car body & chassis alignment, bogie setup | Fast, high-precision over large structures |

3D Scanners | Exterior shell, interiors, seating layouts | Captures freeform surfaces & complex shapes |

Portable CMMs | Onsite part verification, shaft/axle checks | Flexible, rugged, real-time inspection |

Coordinate Measuring Machines (CMMs) | Gearbox housings, brakes, wheel hubs | Repeatable and accurate inspection |

VMMs | Brake discs, rotors, coupler pins | Ideal for small-medium precision parts |

Drones + LiDAR | Track geometry, yard mapping, tunnel inspection | Safe, fast, scalable topographic surveys |

Let’s get started

Caliylark Technologies – Your Trusted Partner in Precision Engineering and 3D Solutions