info@caliylark.com

Marine & Shipbuilding

Marine & Shipbuilding

- Shipbuilding requires precision in large-scale fabrication, where accuracy during modular assembly and retrofitting is critical. Complex geometries and confined ship environments benefit greatly from portable metrology.

Our Products

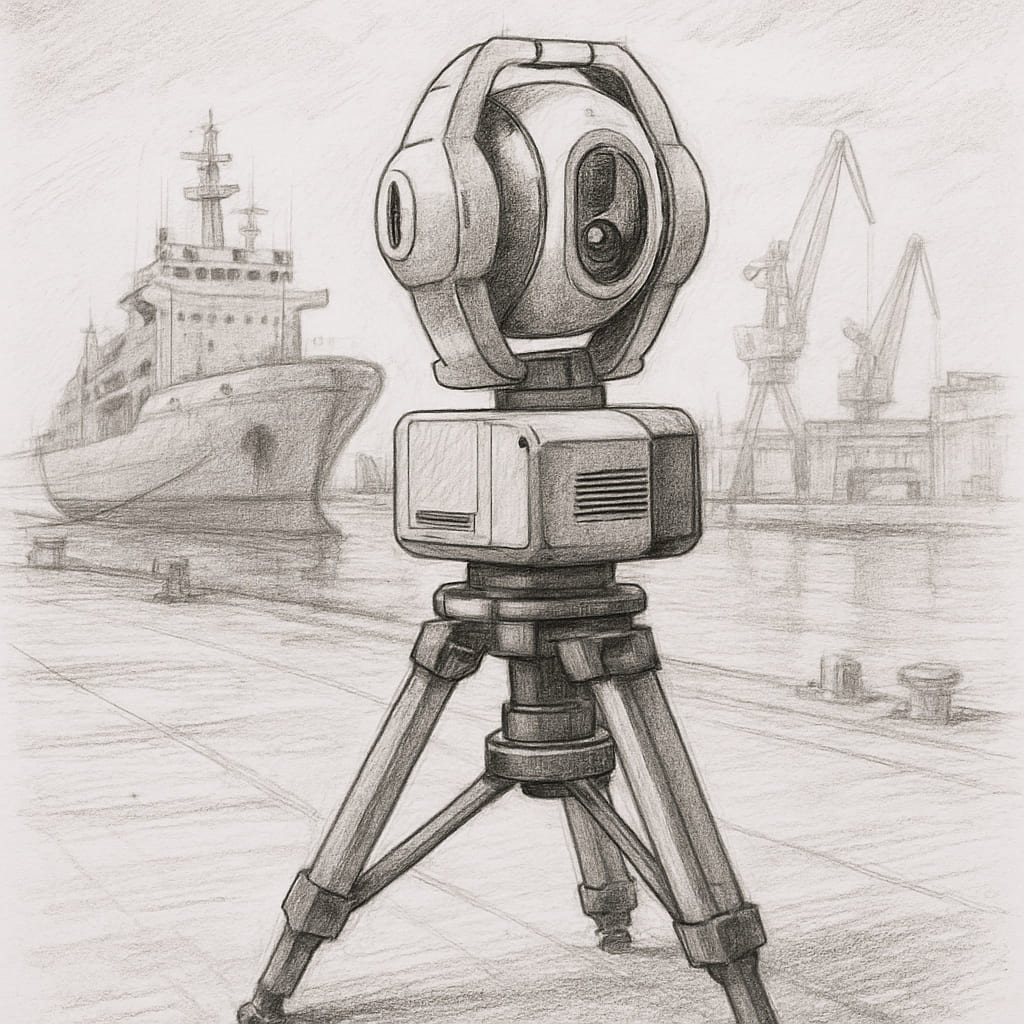

Portable 3D Laser Trackers

Align modular hull sections and ship frames with minimal cumulative error.

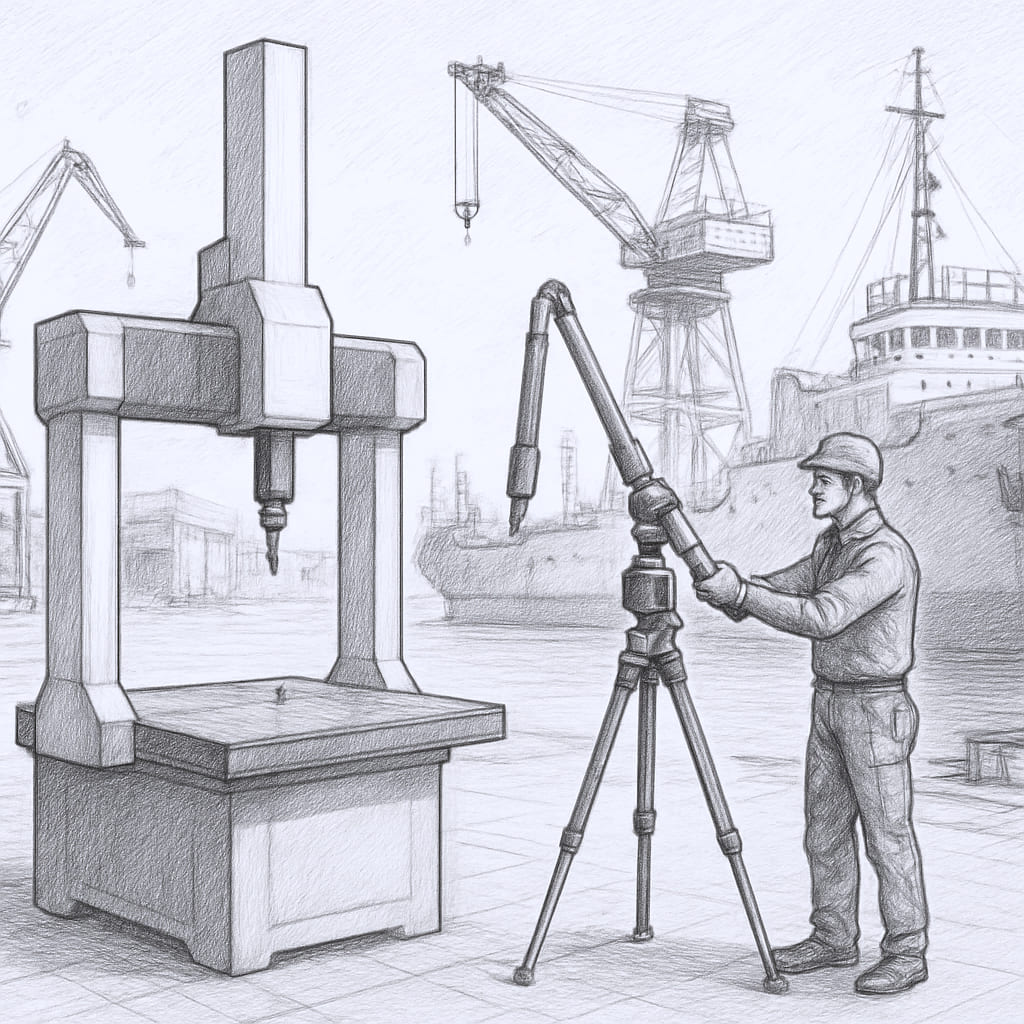

Fixed CMMs & Portable CMMs

Inspect pumps, bearings, flanges, shafts, and propulsion components.

3D Scanners

Capture ship hull curvature, deck layouts, and complex piping systems.

Fiber Laser Markers

Mark serial IDs and maintenance labels that withstand marine environments.

Our Services

Hull & Structure Inspection (3D Scanners)

For dry-dock repairs, deformations, and measurement of wear.

Retrofit Design (3D Scanners & Reverse Engineering)

Enable engine room redesign or piping rerouting.

Part Recreation (CMMs & CNC)

Manufacture of spare parts where original drawings are missing.

Benefits

Minimizes misalignment in modular block construction

Supports marine retrofitting with accurate data

Increases speed and accuracy of dry-dock maintenance

Case Study

A defense shipyard used 3D laser trackers for hull alignment and achieved precise joining across 20+ modular segments, improving build efficiency.

Product | Key Applications | Benefits |

Laser Trackers | Hull, shaft, deck alignment | Large-scale, ultra-precise measurement |

3D Scanners | Propellers, rudders, interior layouts | Non-contact, fast geometry capture |

Portable CMMs | Onsite block, flange, and bracket verification | Lightweight, rugged, easy to deploy |

Drones (UAVs) | Shipyard & offshore structure survey | Safe access to difficult or hazardous areas |

Coordinate Measuring Machines (CMMs) | Propulsion or engine components | Sub-micron level inspection at QA labs |

Fiber Laser Markers | Part identification and traceability | Permanent marine-grade laser markings |

Let’s get started

Caliylark Technologies – Your Trusted Partner in Precision Engineering and 3D Solutions