info@caliylark.com

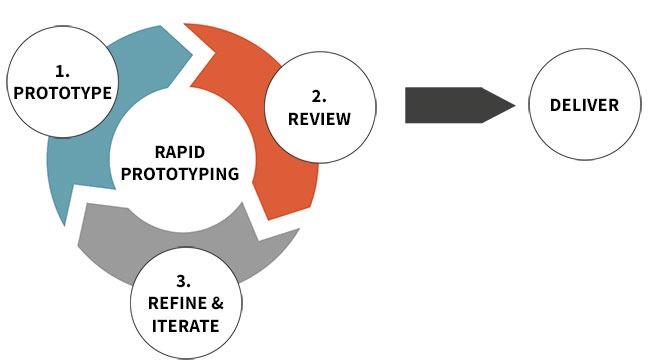

Rapid Prototyping

Rapid Prototyping

Rapid prototyping is the fast fabrication of a physical part, model, or assembly using 3D CAD data. Our service offers quick-turn prototypes using advanced manufacturing methods like 3D printing, CNC machining, vacuum casting, and sheet metal forming—tailored to a wide variety of materials.

Materials We Support

We prototype in a range of engineering-grade materials, including:

- Plastics: ABS, PLA, PETG, Nylon, Polycarbonate, TPU, PEEK

- Metals: Aluminum, Stainless Steel, Titanium, Brass, Copper

- Elastomers & Rubber: Silicone, EPDM, Polyurethane, Neoprene

- Composites & Resins: Carbon Fiber-reinforced plastics, epoxy resins

- Wood, Foams, and Specialty Materials upon request

Services

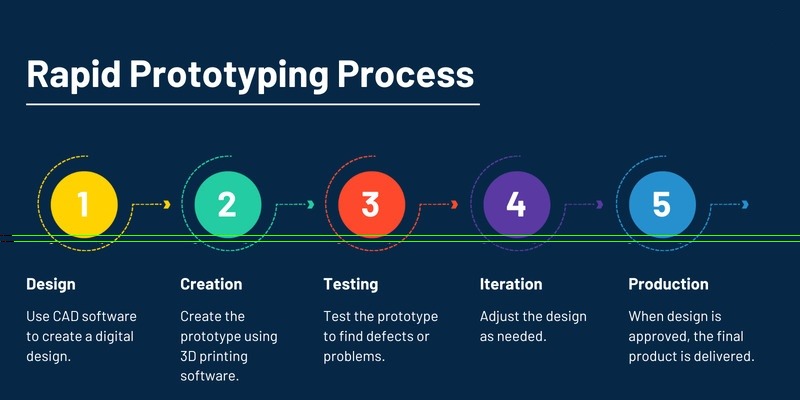

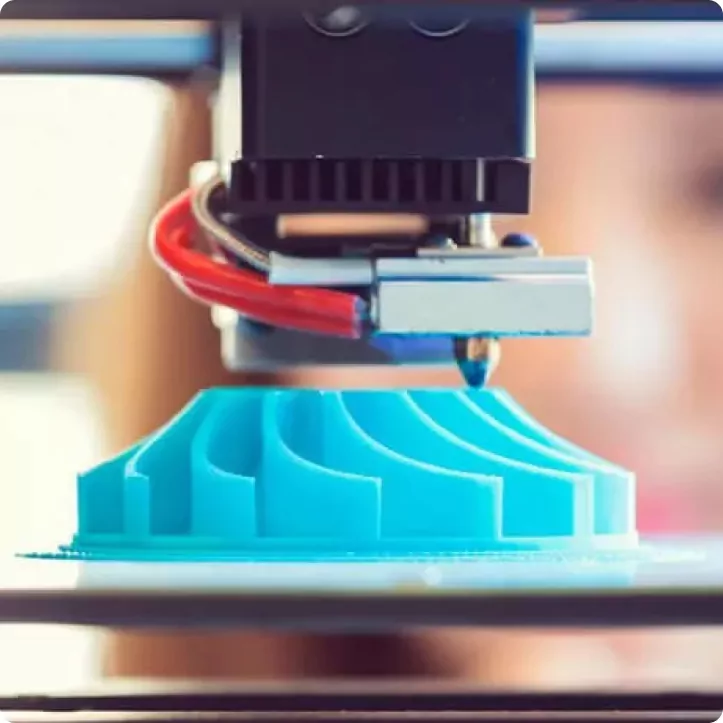

3D printing

Our 3D printing rapid prototyping services are ideal for 3D printed plastics and metals, with extensive material and finishing options available. These additive manufacturing technologies can also sometimes be used for production.

CNC machining

Caliylark operates a large number of CNC machining centers, mills, and lathes (for CNC turning), enabling rapid prototyping of CNC machined parts made from plastic or metal. We offer a wide range of material and finishing options and the potential to combine CNC machining with other rapid prototyping processes.

Vacuum casting

Rapid vacuum casting is a low-cost prototyping service for the production of low-cost plastic parts, particularly items like colorful display models.

Tooling

Rapid tooling (bridge tooling or prototype tooling) refers to the rapid CNC machining of metal tooling for injection molding. It is therefore the first step toward rapid injection molding.

Sheet metal prototyping

Rapid sheet metal prototyping is a set of rapid prototyping services for the production of sheet metal parts. This includes various forming, cutting, and assembly processes for manipulating the sheet metal stock in different ways.

Metal casting

Casting is generally considered a production process for high-quality metal parts, but rapid metal casting — using 3D printing to make low-cost patterns — offers an affordable route for prototyping cast metal.

Prototyping Capabilities

Choose the best process based on your material and application:

Process | Materials | Use Case |

3D Printing (FDM/SLA/SLS) | Plastics, Resins, Nylon | Concept models, fit testing, early-stage designs |

CNC Machining | Metals, Plastics | Functional parts, jigs, end-use components |

Vacuum Casting | Polyurethane, Silicone | Low-volume runs, soft-touch parts, enclosures |

Sheet Metal Prototyping | Stainless Steel, Aluminum | Brackets, enclosures, panels |

Injection Molding (Rapid Tooling) | Thermoplastics | Bridge tooling, pre-production parts |

Industries We Serve

We prototype for diverse industries including:

- Automotive – Dashboard panels, engine components

- Aerospace – Lightweight structural parts, interior fittings

- Medical – Surgical guides, ergonomic tools

- Consumer Electronics – Enclosures, housings, buttons

- Robotics & Automation – Gears, brackets, sensor mounts

- Education & R&D – Lab models, teaching tools, experimental parts

Why Choose Us?

- Material Flexibility for every design requirement

- Fast Lead Times – parts delivered in 2–7 days

- In-House Design Support & DFM review

- ISO-Certified Processes & Tight Tolerances

- Cost-effective Low-Volume Production

Delivery Formats

One-off Prototypes

Batch Production

Assemblies & Finished Models

Dimensional Inspection Reports on Request

Let’s get started

Caliylark Technologies – Your Trusted Partner in Precision Engineering and 3D Solutions