info@caliylark.com

Video Measuring Machine

Video Measuring Machine

Video Measuring Machines (VMMs) are precision optical metrology systems that perform non-contact dimensional measurement using high-resolution cameras, advanced optics, and intelligent image processing algorithms. These machines are specifically designed for inspecting intricate geometries, delicate parts, and micro-components that cannot be measured easily using traditional tactile methods. By using edge detection, lighting control, and programmable measurement paths, VMMs offer a fast, accurate, and repeatable solution for 2D and 3D dimensional inspection.

At Caliylark Technologies, our Video Measuring Machines are engineered for high-throughput, high-accuracy applications in quality control environments. Available in both manual and fully automated models, our VMMs feature motorized zoom, programmable stage movement, autofocus, and multi-angle lighting—ensuring superior measurement consistency and detailed data capture for even the most complex or fragile components.

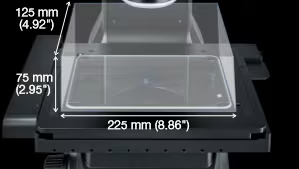

Large Field-of-View

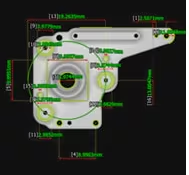

High-Accuracy, Optical Inspection

Instant Measurement Results

Key Features:

High-resolution imaging with sub-micron accuracy

Non-contact inspection using telecentric optics and edge-detection algorithms

Precision XY measuring stages with granite base construction for stability

Automated Z-axis height measurement and 3D profiling (optional on select models)

Multiple illumination sources: coaxial, ring light, contour, and backlighting

Software integration for feature recognition, pattern matching, GD&T analysis, and CAD comparison

Benefits:

Video Measuring Machines eliminate physical contact with parts, making them perfect for inspecting components prone to deformation, scratching, or wear under tactile probes. Their non-contact nature ensures precision without compromising the part, particularly for small, soft, or highly polished surfaces.